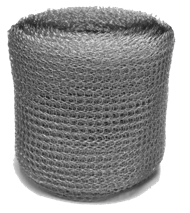

CWI Tech-Mesh™ is available from stock in a wide range of alloys. 300 series stainless steel is a popular option for demister pad material, as it provides an effective balance of strength and corrosion resistance. Known for its ability to withstand harsh environments and extreme working conditions, CWI Tech-Mesh™ is specifically engineered to endure all the challenges faced by oil and gas industries. Whether you are replacing an existing unit or specifying a custom solution, Central Wire offers only the highest quality finished products.

Need a different demister pad material? Other alloys are always available upon request. Visit our specialty alloys page for additional information about our copper and nickel alloys, such as Monel®, Inconel® and 20Cb3. As an added benefit, CWI Tech-Mesh™ uses only made in the USA materials provided by other Central Wire factories. Having a close-knit supply chain means you can get the exact product you need without sacrificing your quality standards.

Download a copy of our alloys guide for convenient referencing, and do not hesitate to contact us with any additional questions.

CWI 304 (UNS: S30400) is a basic, austenitic stainless steel containing a minimum of 18% chromium and 8% nickel. This material meets the chemistry of the ASTM A580 specification.

CWI Series Stainless 304L (UNS S30403) is a low carbon variation of Type 304 with a 0.03% maximum carbon content. This material meets the chemistry of the ASTM A580 specification.

CWI Series Stainless 316 is an austenitic chromium-nickel-molybdenum stainless steel with good general corrosion resistance and improved pitting resistance. UNS S31600 – Cr: 16.0-18.0%, Ni: 10.0 – 14.0%, Mo: 2.0-3.0% with full chemistry to ASTM A580

The low carbon content in CWI Series Stainless 316L is intended to minimize the occurrence of grain boundary carbide precipitation. UNS S31603 – C: 0.03% max, Cr: 16.0-18.0%, Ni: 10.0-14.0%, Mo: 2.0-3.0% with full chemistry to ASTM A580

CWI Series Stainless 317L is a molybdenum bearing austenitic stainless steel with improved corrosion resistance over type 304/304L and type 316/316L stainless steel. UNS S31703 – C: 0.03%m max, Cr: 18.0-20.0%, Mo: 3.0-4.0% and Ni: 11.0-15.0% with full chemistry to ASTM A580

CWI Series Stainless 321 is a titanium stabilized austenitic stainless steel commonly used for service in the temperature range of 1000°F (538°C) to 1600°F (870°C).UNS S32100 – Cr: 17.0-19.0%, Ni: 9.0-12.0%, Ti: 5xC min with full chemistry to ASTM A580

CWI Series Stainless 347 is an austenitic stainless steel alloyed with columbium (niobium) offering an excellent resistance to intergranular corrosion. UNS S34700 – Cr: 17.0-19.0%, Ni: 9.0-13.0%, Cb: 10xC min with full chemistry to ASTM A580

| Alloy | C | Mn | Si | P | S | Cr | Ni | Mo | Cu | Co | Al | Ti | N | Cb | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.08% max | 2.00% max | 1.00% max | 0.040% max | 0.030% max | 18.00- 20.00% | 8.00- 10.00% | 0.75% max | 0.75% max | ||||||

| 304L | 0.030% max | 1.25-2.00% max | 0.20-0.75 | 0.030% max | 0.015% max | 18.0-19.0% | 8.75-19.0% | 8.75-9.75% | 0.50% max | 0.50% max | 0.015% max | 0.050% max | |||

| 316 | 0.035-0.070% | 1.0-2.0% | 0.70% max | 0.040% max | 0.015% max | 16.5-18.0% | 10.50 – 12.0% | 2.0-3.0% | 0.50% max | 0.30% max | 0.010% max | 0.03% max | 0.060% max | 0.05% max | |

| 316L | 0.03% max | 1.25-2.00% | 0.25-0.75% | 0.040% max | 0.030% max | 16.5-18.0% | 10.5-11.0% | 2.0-2.25% | 0.60% max | 0.070% max | |||||

| 317L | 0.03%max | 2.0% max | 0.75% max | 0.045% max | 0.030% max | 18.0-20.0% | 11.0-15.0% | 3.0-4.0% | 0.50% max | 0.050% max | |||||

| 321 | 0.020-0.060% | 1.25-2.00% | 0.40-0.80% | 0.030% max | 0.010% max | 17.0-19.0% | 9.0-11.0% | 0.60% max | 0.50% max | 0.50% max | 0.150% max | 5xC(C+N)-0.70% | 0.040% max | ||

| 347 | 0.040-0.060% | 2.00% max | 1.00% max | 0.040% max | 0.015% max | 17.0-19.0% | 9.0-12.0% | 0.50% max | 0.50% max | 0.060% max |